Latches have been the unsung heroes of security for centuries, shaping civilizations in ways you might not even imagine. You’ve likely taken for granted the evolution of these essential devices, from basic wooden bars in ancient Egypt to today’s sleek, digitally controlled mechanisms. As you consider how these innovations reflect societal shifts, you might wonder what secrets lie beneath their surface. What stories do they tell about our need for safety and artistry? Let’s explore the intricate journey of latches and what they reveal about human ingenuity.

Key Takeaways

- Latches first emerged in ancient civilizations, demonstrating advanced engineering to secure doors and symbolize stability in society.

- The Industrial Revolution enabled mass production of latches, increasing accessibility and affordability for consumers.

- Innovations such as spring latches and bolt latches improved security measures, adapting to urban living challenges of the 19th century.

- Modern latches incorporate smart technology, varying from keyless entry systems to biometric authentication, enhancing convenience and security.

- Future trends in latch design emphasize sustainability and aesthetic appeal, blending security with decorative hardware elements in home design.

Ancient Egyptian Innovations

Latches in ancient Egypt weren’t just utilitarian tools; they represented a blend of engineering and artistry that reflected the culture’s advanced understanding of security and design.

These mechanisms employed materials like wood and metal, showcasing the Egyptians’ proficiency in crafting durable, functional devices. You’d notice that their latches often included intricate carvings, illustrating both practical utility and aesthetic appeal.

Additionally, they integrated complex locking systems that deterred theft, underscoring the society’s emphasis on safeguarding property. The strategic placement of these latches indicated not only architectural ingenuity but also social hierarchies, as more elaborate systems were reserved for the elite.

Within this framework, latches weren’t merely objects; they were symbols of stability and order in a bustling civilization.

Greek and Roman Mechanisms

You’ll find that Greek and Roman innovations in latch mechanisms were pivotal in enhancing security and practicality.

Their use of bronze door hinges allowed for smoother operation and durability, while advanced locking systems showcased an early understanding of complex security measures.

Moreover, key security innovations laid the groundwork for the locks we rely on today, reflecting a remarkable evolution in protective design.

Bronze Door Hinges

While many innovations from ancient civilizations have shaped modern architecture, the bronze door hinges used in Greek and Roman mechanisms stand out as a demonstration of their engineering prowess.

These hinges, crafted from durable bronze, provided both functionality and aesthetic appeal. You’d appreciate how their design facilitated smooth operation, accommodating the often massive stone doors common in grand structures.

The intricate craftsmanship reflected not only a mastery of materials but also an understanding of structural integrity and weight distribution. Moreover, their resistance to corrosion made them ideal for long-lasting applications in temples and public buildings.

Advanced Locking Systems

The innovations in bronze door hinges naturally paved the way for advancements in locking mechanisms within Greek and Roman architecture.

You’ll find that these ancient cultures explored several sophisticated solutions to protect their valuable possessions and structures:

- Wooden Bar Locks: Simple yet effective, often reinforced with metal.

- Pivoting Pins: Enabled secure closures in doors by using gravity.

- Warded Locks: Featured intricate designs to enhance security against unauthorized access.

- Sinew and Rope Systems: Harnessed natural materials for securing doors and gates effectively.

- Tumbler Mechanisms: Early forms of combination locks provided unique locking solutions. Additionally, these early systems laid the foundations for later innovations such as lock re-keying to improve security without replacing the entire lock.

These mechanisms showcase a keen understanding of both functionality and security, reflecting the importance of protection in their societal contexts. Furthermore, the principles of high-security locks developed from these ancient innovations have continued to evolve, emphasizing enhanced protection and durability in modern security solutions.

The ingenuity displayed in their designs laid groundwork for future developments in locking systems.

Key Security Innovations

As ancient civilizations sought to enhance security, key innovations emerged that revolutionized the way doors were locked.

In ancient Greece, craftsmen developed intricate bolt mechanisms operated by wooden keys, showcasing early engineering sophistication. These early systems began to establish a foundation for advanced designs that would evolve in future locking mechanisms.

Meanwhile, the Romans perfected these designs, introducing metal keys that reflected a leap in durability and complexity. These keys operated on tumblers, a mechanism that increased resistance to unauthorized access. Such advancements weren’t merely practical; they became status symbols, indicating wealth and power.

Surveillance concepts, like the use of guards in conjunction with secure locks, began to evolve. This interplay between key innovation and security set the stage for modern systems, underscoring the significance of these ancient mechanisms in the ongoing quest for safety and privacy. Additionally, these early systems laid the groundwork for future advancements in key control systems, which would further enhance security measures over time.

Latches in the Middle Ages

During the Middle Ages, when security became paramount for homes and fortifications alike, latches evolved considerably, reflecting both practical needs and sociopolitical influences of the time.

These advancements were integral to the rising complexity of architecture and increased threats from conflict. You’d find the following developments in latch design:

- Simplicity and Strength: Basic wooden latches strengthened entrances.

- Crossbar Mechanisms: Improved securing methods for larger doors.

- Intricate Designs: Ornate metal latches signified wealth and status.

- Key-operated Latches: Beginnings of more sophisticated locking systems emerged.

- Community Significance: Latches became symbols of both personal and communal safety.

These innovations weren’t just functional; they represented a shift in how people viewed security in an increasingly volatile world.

Industrial Revolution Advancements

With the onset of the Industrial Revolution, latch technology underwent transformative changes that mirrored the era’s rapid industrialization and urbanization.

You’ll notice that mass production techniques enabled manufacturers to create latches with greater efficiency and consistency. Mechanized tools replaced handcrafting, elevating precision in design and function.

During this period, innovations such as the bolt latch emerged, featuring improved security and ease of use, tailored for burgeoning factory environments and urban residences. The implementation of high-security locks in some industrial settings highlighted an early recognition of the importance of enhanced safety features.

Additionally, the introduction of new materials like wrought iron and steel enhanced durability, catering to the demands of an industrial society.

As security needs evolved, it became increasingly important to prioritize security upgrades in lock design, laying the foundation for future advancements in safety.

As you explore this evolution, recognize how these advancements not only fulfilled practical needs but also laid the groundwork for future locking mechanisms, shaping safety and convenience in modern life.

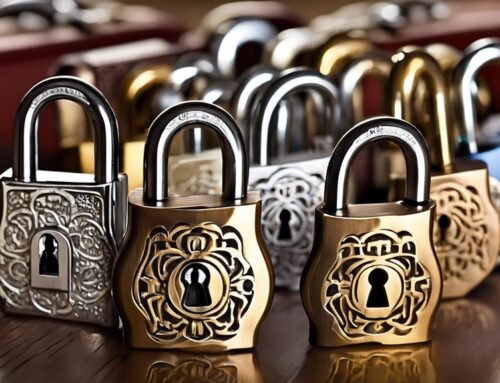

Decorative Locks of the 17th Century

The advancements in latch technology during the Industrial Revolution set the stage for a new wave of decorative locks in the 17th century, where function met artistry.

These locks became a statement of wealth and craftsmanship, blending utility with intricate designs that reflected cultural values. High-security features such as mechanical security enhancements began to emerge, increasing the functionality of these decorative locks.

You’d find elements such as:

- Ornate engravings depicting royal emblems

- Elaborate shapes and designs reflecting Baroque aesthetics

- Use of high-quality materials like brass and iron

- Functionality enhanced by innovative mechanisms

- Signature motifs that identified skilled artisans

These decorative locks weren’t mere security devices; they symbolized status and artistry in a time ripe for expression. Notably, the integration of high-security locks from advanced manufacturers began to influence both aesthetics and functionality in subsequent innovations.

As you explore deeper into this era, you’ll uncover how form considerably influenced function, marking the evolution of locking mechanisms.

Evolution in the 19th Century

As the Industrial Revolution gained momentum in the 19th century, advancements in manufacturing and materials dramatically transformed latch and lock design.

You’ll notice an emphasis on mechanization with mass production, making latches more affordable and accessible. Innovations like the invention of the spring latch improved functionality, offering both security and ease of use. Investing in high-quality locks can significantly enhance security features that were becoming increasingly vital during this transformative era.

Additionally, the introduction of iron casting allowed for stronger, more durable designs, while decorative elements emerged, reflecting the aesthetic values of the time.

This period saw the standardization of latch sizes and types, facilitating interoperability across various applications.

Lock replacement is essential for maintaining security in commercial properties, ensuring that advancements in design are fully utilized.

You’d appreciate how these changes not only enhanced security but also influenced the architectural styles of the age, marrying form with function in a rapidly evolving society.

Modern Latch-Mediated Technologies

While advancements in technology have fundamentally reshaped latch design in contemporary society, modern latch-mediated technologies go beyond simple locking mechanisms to integrate with smart home systems and security networks.

These innovations offer enhanced convenience, safety, and control. As you consider these technologies, note their implications:

- Smart keyless entry systems using biometric authentication

- Remote locking and releasing via smartphone applications

- Integrated security features like alarms and alerts, which utilize communication protocols for compatibility

- Auto-lock functionalities based on user proximity

- Energy-efficient designs merging aesthetics with functionality

In mastering these technologies, you not only elevate security measures but also modernize your living environment. Additionally, features such as robust encryption ensure your smart lock systems remain secure from hacking attempts.

As the landscape of latch design transforms, it’s essential to understand how these systems work in concert to deepen your strategic approach to home security and management.

Biological Comparisons of Latch Systems

Exploring modern latch-mediated technologies reveals intriguing parallels with biological systems that utilize latch mechanisms for security and functionality.

Consider the molecular latch found in transmembrane proteins, which regulate cellular entry and exit. These proteins employ conformational changes akin to mechanical latches, ensuring selective permeability.

Similarly, muscle fibers use latch bridges in actin-myosin interactions, enabling efficient force generation while minimizing energy expenditure.

In the plant kingdom, guard cells regulate stomatal openings through latch-like mechanisms, controlling gas exchange with the environment.

In all these instances, biological latches serve to maintain homeostasis and adaptiveness, mirroring technological advancements in latches that offer enhanced security and efficiency.

Historical Perspectives on Locks

Locks have evolved greatly throughout history, reflecting the changing needs for security and privacy in human societies. From the rudimentary mechanisms of ancient Mesopotamia to the intricate designs of the Renaissance, each era’s locks mirror its cultural priorities.

- The first known locks date back to 4000 BCE in Egypt.

- The use of bronze markedly advanced locking mechanisms around 3000 BCE.

- The invention of the key led to greater security and control over access. This innovation laid the groundwork for various lock grades which categorize locks based on their security features.

- Medieval Europe saw the rise of decorative locks that also served as status symbols.

- Modern advancements include electronic locks, addressing contemporary needs for convenience and security. Choosing the Perfect Lock can help homeowners determine the best locking solutions for their specific needs.

Understanding these historical contexts helps you appreciate how locks’ functionality and aesthetic value have intertwined through time.

Innovations in Door Hardware

As you explore innovations in door hardware, consider how mass production has transformed accessibility and affordability, allowing for a wider range of choices.

You’ll also notice the emergence of advanced lock mechanisms that enhance security, integrating smart technology for modern convenience.

Finally, decorative hardware innovations have redefined aesthetics, merging function with style to cater to diverse design preferences. Additionally, the rise of digital keyless locks has revolutionized home security, providing users with more control and flexibility in managing access to their homes.

Mass Production Impact

While the advent of mass production revolutionized numerous industries, its impact on door hardware has been particularly profound.

You’ve likely noticed how this transformation has led to both increased accessibility and innovation in design.

The changes in door hardware due to mass production include:

- Standardized sizes for easier installation

- Economies of scale resulting in lower costs

- Greater variety in materials and finishes

- Enhanced durability through improved manufacturing processes

- Broader availability across different markets

With these advancements, you can appreciate the significance of mass production in making sophisticated door hardware accessible to the average consumer.

The efficiency and innovation from this process have fundamentally altered how you experience and interact with everyday entrances, turning functional elements into design statements.

Advanced Lock Mechanisms

With advancements in technology shaping the way we secure our spaces, modern lock mechanisms have evolved far beyond traditional options.

You’ve got smart locks utilizing keyless entry, offering both convenience and enhanced security through biometric authentication and mobile connectivity. These systems, often integrated with home automation, allow you to control access remotely, providing peace of mind.

Electronic deadbolts also present a reliable alternative to mechanical locks, featuring reinforced materials and advanced algorithms that resist tampering.

Additionally, you’ll find high-security locks incorporating unique pin tumbler designs, making unauthorized access exceedingly difficult.

As you explore these innovations, consider the implications on security, convenience, and even aesthetics in your choice of door hardware, ensuring you stay ahead in safeguarding your environment.

Decorative Hardware Innovations

Modern advancements in lock mechanisms haven’t only enhanced security but also opened doors to innovative designs in decorative hardware.

These innovations blend aesthetics with functionality, inviting homeowners to elevate their spaces without compromising safety. You’ll find a wealth of options that cater to personal style while maintaining durability.

- Smart locks with customizable finishes

- Vintage-inspired deadbolts for a classic touch

- Elegant handlesets combining form and function

- Designer hinges that complement interior styles

- Eco-friendly materials in modern hardware design

Each innovation showcases the balance between security and style, allowing you to express individuality while ensuring protection.

As trends evolve, the importance of integrating artistic flair with robust lock mechanisms continues to shape the future of decorative hardware.

Frequently Asked Questions

What Materials Were Commonly Used for Early Latches and Locks?

In early latches and locks, materials like wood, bronze, and iron predominated.

You’d find wooden latches primarily in domestic settings, offering basic security.

Bronze, valued for its durability and resistance to corrosion, was often used for more intricate designs.

Iron emerged later, favored for its strength in forging robust lock mechanisms.

Each material revealed unique properties that catered to specific security needs, shaping how you’d approach safeguarding spaces throughout history.

How Did Latch Technology Influence Home Security Throughout History?

Latch technology greatly influenced home security by creating barriers against unauthorized access.

You notice that as latches evolved in complexity, they enhanced safeguarding techniques. Simple wooden mechanisms transformed into intricate designs, enabling better locking systems.

With each improvement, homeowners gained confidence, directly impacting society’s perception of safety.

Over time, these developments fostered increased architectural designs emphasizing secure entry points, ultimately shaping how you approach home security today.

Were There Any Cultural Differences in Latch Designs Across Civilizations?

Cultural differences in latch designs reveal much about societal values and craftsmanship.

In Ancient Egypt, you’d find intricate, ornate latches reflecting wealth, while Scandinavian designs prioritized functionality and simplicity, showcasing a minimalist approach.

Asian designs often integrated intricate locking mechanisms, highlighting innovation and security.

What Role Did Artisans Play in the Evolution of Latches and Locks?

Artisans have played an essential role in the evolution of latches and locks by expertly crafting designs that address security needs and aesthetics.

You’ll notice that their skill enabled adaptations tailored to specific cultural demands, enhancing functionality over time.

This craftsmanship not only involved the selection of durable materials but also the incorporation of intricate mechanisms, reflecting a blend of artistry and practicality that shaped user trust in these vital devices throughout history.

How Have Latches Adapted to Modern Smart Home Technologies?

Latches have leaped into the landscape of modern smart home technologies, seamlessly integrating into your digital daily life.

You’ll find smart latches that connect wirelessly, allowing you to lock or open doors remotely. Many feature fingerprint recognition and mobile app control, enhancing security considerably.

As ease and efficiency reign supreme, these innovations redefine convenience, turning traditional access methods into sophisticated, customizable solutions that align with contemporary lifestyles.

Embrace the future of home security!

Conclusion

In tracing the evolution of latches, you’ve seen how each era added its own twist to security and convenience, much like the layers of a fine onion. From ancient wooden barriers to today’s sleek biometric systems, the journey reflects not just advancements in technology but also a continuous response to human needs. As you open the door to the future, remember that each latch tells a story, blending history with innovation in every turn and click.